من نحن

ايه.اتش .ام للتجارة والتوريدات

ايه.اتش .ام للصناعة

ايه.اتش .ام للهندسة والمقاولات

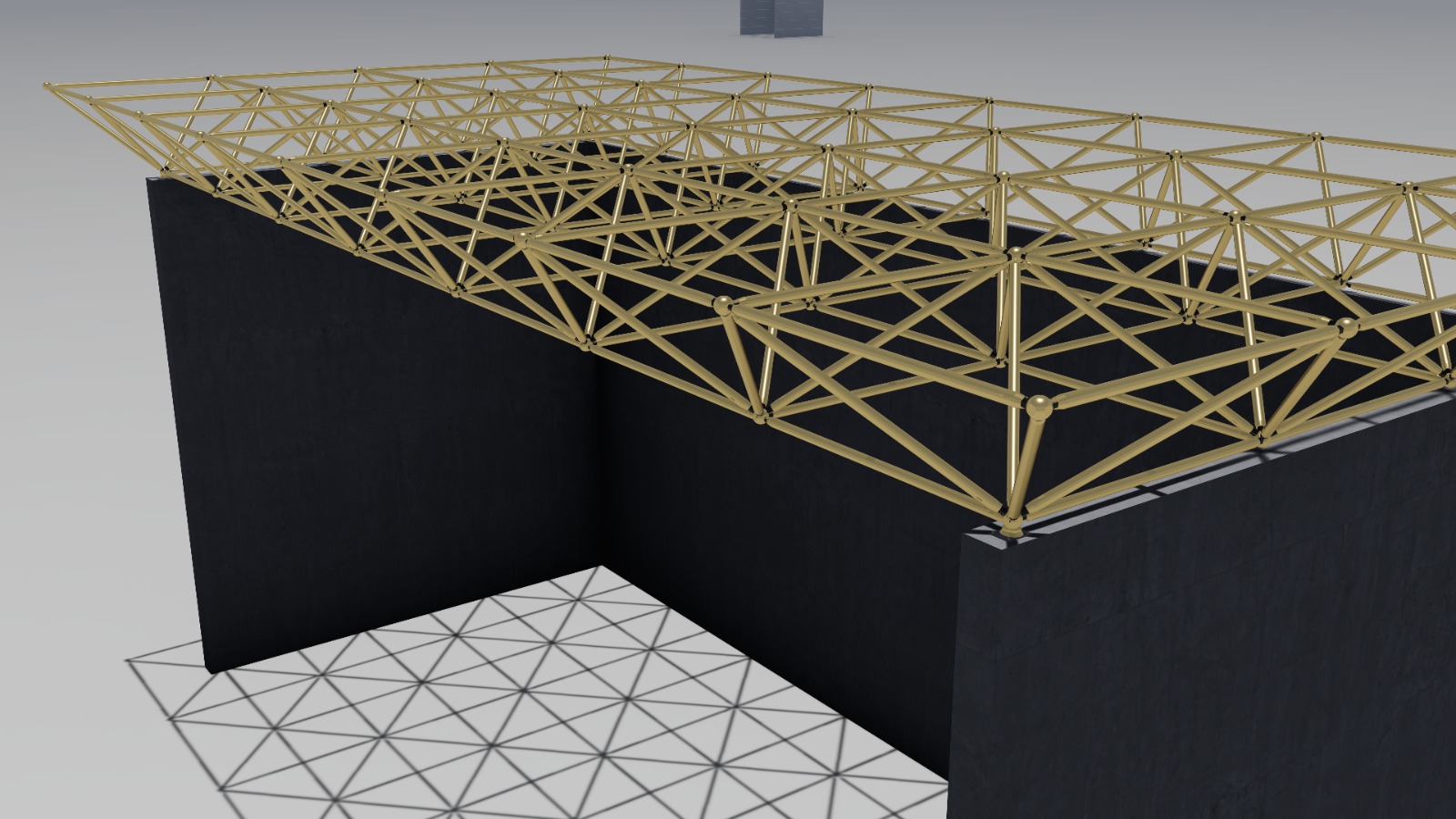

ايه.اتش.ام للتجارة والتوريدات : وكيل وموزع حصري للعديد من الماركات العالمية والمصانع الاوروبية في مصر وافريقيا والشرق الاوسط , وذلك في مجال الاسقف والكلادينج والعوزال والقباب والتغطيات السماوية والاسبيس فريم سيستم

ايه.اتش.ام للصناعة:استخدمت احدث اساليب التكنولوجيا الألمانية في الصناعة المصرية واصبح لديها خط انتاج كامل فلات وخط تكريب اوتوماتيكي لأنظمة الاستاندينج سيم بالصاج والألمونيوم وانتاج الواح عزل

.ساندويتش بانل بالصوف الصخري واليو بي في سي UPVC وتصنيع جميع انواع الهياكل المعدنيه

ايه .اتش.ام للهندسة والمقاولات: لديها ادارة هندسية متكاملة وفريق عمل متميز لانجاز وتنفيذ جميع المشروعات المتخصصة بأعلي معايير الجودة والسلامة وفقا للجداول الزمنية المحددة. منتجاتنا الرئيسيه

جميع الأنواع من ألواح وانظمة البولى كربونيت - ألواح الألومنيوم كلادينج – الواح (يو بى فى سى) البديل الافضل للصاج المعرج - الواح (بى فى سى) القرميد البلاستيكى البديل الافضل للقرميد الفخاري

الصوف الصخرى -أنظمة ستاندينج سيم -

مهمتنا

منتجاتنا الرئيسيه :

جميع الأنواع من ألواح وانظمة البولى كربونيت - الاسبيس فريم سيستم - سوفت بانل – الواح (يو بى فى سى) البديل الافضل للصاج المعرج - الواح (بى فى سى) القرميد البلاستيكى البديل الافضل للقرميد الفخاري – أنظمة ستاندينج سيم.

رؤيتنا

رضا عملاءنا هو هدفنا,

رؤيه الشركه هي تقديم افضل المنتجات في مجال التغطيات و الصناعات المعدنيه بأحسن و أجود الخامات العالميه و تصميمات ديكوريه مبتكرة

فريقنا

تمتلك ايه اتش ام جروب مجموعه متميزه من الأدارات على قدر عالى من التميز والاحترافيه المطلوبه فى سوق العمل وهذا ما يميزها عن باقى منافسيها فى السوق المصرى .

المشروعات

.jpg)

مطار النزهة

.jpeg)

مول بور فؤاد

.jpg)

مطار الجميل

.jpg)

مشروع صوفي باك

.jpg)

ماك اويل

.jpg)

قبة كلية طب عين شمس

.jpg)

سكاي لايت معهد الرخام ببني سويف

.jpeg)

بوابه مطار. ميجالوكس الغردقه

.jpg)

مزارع الثروه السمكيه

.jpg)

شركه المياه بالغردقه

.jpg)

جامعه سينا

.jpg)

جامعه كفر الشيخ

.jpg)

جامعه الاهرام الكنديه

.jpg)

سوميد للبترول

.jpg)

مطعم ابن البلد

.jpg)

مول الشروق

.jpg)

ماك اويل

.jpg)

بنك الاستثمار القومي

.jpg)

معهد الرخام ببني سويف

(2) (1).jpeg)

مشروع مصر الخير

.jpg)

نادي الشطبي

.jpg)

مشروع ميجا مول اكتوبر

.jpg)

النادي الاجتماعي بالسويس

.jpg)

دير القديسة دميانة

.jpg)

جامعة بنها

.jpeg)

عدلي منصور المركزية التبادلية

بوابات اكتوبر

.jpg)

شركة بتروجيت PMS مبني

.jpg)

مطار شرم الشيخ

.jpg)

مدرسة انترناشونال بمدينة بدر

.jpg)

سلالم المترو الخط الجديد

.jpg)

مبني النائب العام

.jpg)

مدرسة انترناشونال بمدينة بدر

.jpg)

مطعم بوراك

(1) (1).jpg)

مخازن المونوريل

.jpg)

سكاى الطبى

.jpg)

كافيهات مدينة نصر

معهد الرخام ببنى سويف

.jpg)

مطار بغداد

(2).jpg)

اسبيس فريم النادي الاوليمبي

.jpg)

مدرسة انترناشونال بمدينة بدر

.jpg)

مبني خدمات البترول الجوية

(1).jpg)

جابكو

ميناء ابو قير

.jpg)

.jpg)

.jpg)

.jpg)